x

S

A

Y

A

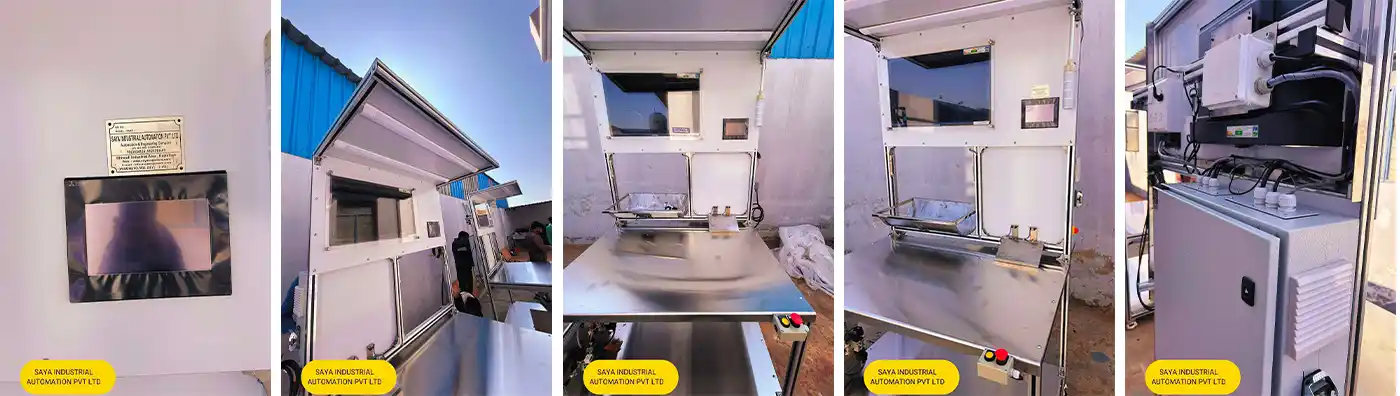

Assembly Stations

Assembly Stations

(Customized & Fully Integrated)

Smart

Interlocked

Process-Driven Assembly Solutions

Specifications & Features:

- Available in Aluminum or Iron Structure — based on customer requirement

- Includes custom-designed jigs & fixtures

- Fully integrated process setup with zero human interference — 100% interlocked system

- SOP-based station design for standardized operation

- Initial design presented in 3D layout → DAP → Manufacturing starts only after client approval

- Custom-built control panels with multiple options:

- PLC: Mitsubishi / Siemens / Delta / Allen Bradley

- HMI & control logic tailored to the process

- Compatible with existing tools and machines

Optional features:

- Vision system integration

- Auto quality check for parts

- Data traceability integration

- Castor wheels (optional, for mobility)

Key Advantages:

- Achieves best cycle time with a user-friendly design

- Ensures repeatability, precision, and operator safety

- Highly ROI-efficient — Return on Investment within 8–10 months in most cases

- Simplifies quality assurance with auto inspection features

- Flexible design to match your workflow and infrastructure

Applications:

- Automotive component assembly

- Electronics manufacturing lines

- Consumer goods production setups

- Specialized SPM-based workflows