x

S

A

Y

A

Data Traceability/Data Logging/ Industry 4.0

ANDON System & Data

Traceability Solution

Real-time Monitoring for Smarter Manufacturing

Product Specifications:

- Type: Custom-Built ANDON & Data Monitoring System

- Display: Custom-sized LED / LCD screens

- Software: Tailored dashboard with live data streaming

- Functionality Includes:

- Production data monitoring & storage

- Machine performance & downtime tracking

- Tact time monitoring for every process

- Assembly line health monitoring

- Interlocking with existing machines (PLC/Relay-based)

Key Advantages:

- Real-time production visibility from inside or outside the plant

- Cloud-based monitoring — accessible remotely

- Helps reduce downtime, track cycle time, and boost OEE

- Fully customizable as per plant size, process & data points

- Easy integration with legacy or modern equipment

Applications:

- Automotive & Assembly Lines

- Electronics & Consumer Goods Manufacturing

- Packaging & FMCG Plants

- Any industry needing process transparency & reporting

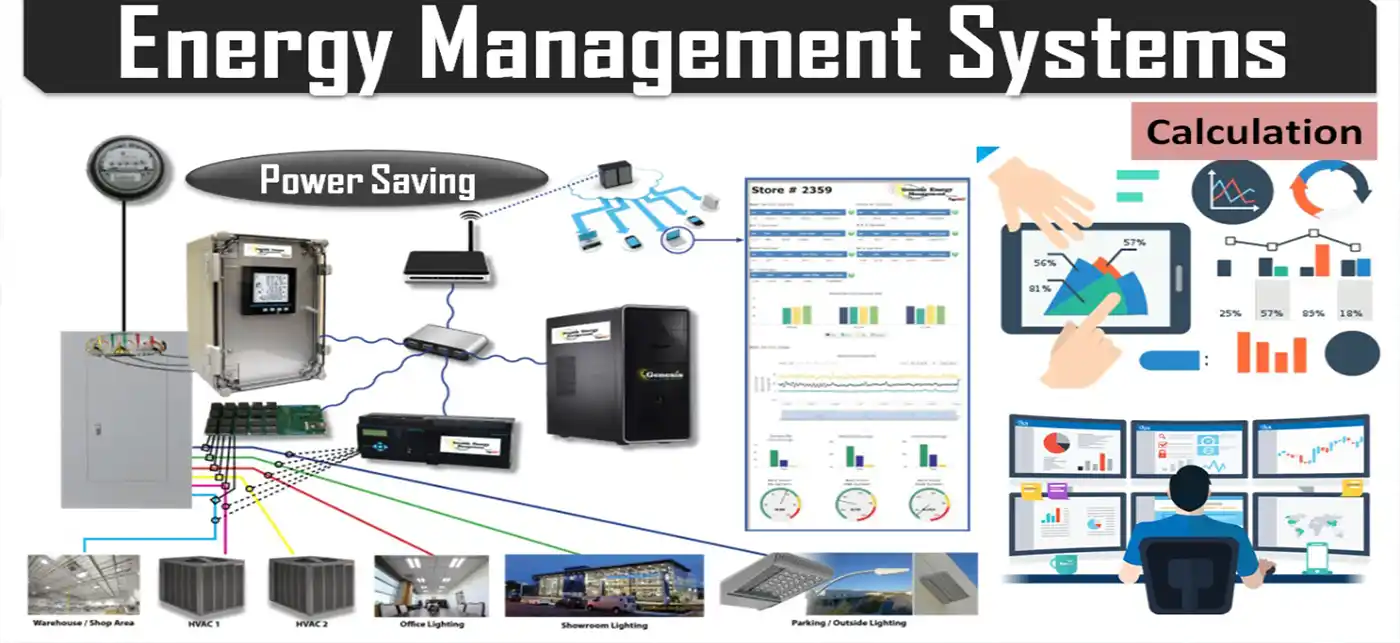

ENERGY MANAGEMENT SYSTEM

Key Functions of EMS:

Energy monitoring:

Tracks real-time energy usage across machines, buildings, or plants.

Data logging and analysis:

Collects and analyzes historical data for trends and inefficiencies.

Reporting:

Generates reports for energy consumption, cost analysis, and carbon footprint.

Alarming and notifications:

Alerts for abnormal consumption or

equipment malfunction.

equipment malfunction.

Control and automation:

Integrates with systems like HVAC or lighting to automate operations based on energy demand.

Benefits of Implementing EMS

- Reduced energy bills

- Improved operational efficiency

- Sustainability and carbon reduction

- Regulatory compliance

- Better decision-making with real-time data

EMS APPLICATION

- Manufacturing industries

- Commercial buildings and campuses

- Hospitals and data centers

- Utilities and power plants