Step 1:

GENBA – UNDERSTANDING THE ACTUAL SITUATION FOR CUSTOMIZED SOLUTION

GENBA – UNDERSTANDING THE ACTUAL SITUATION FOR CUSTOMIZED SOLUTION

CONCEPT SHARING WITH CLIENT FOR INITIAL ALIGNMENT

3D DESIGN DEVELOPMENT AFTER CONCEPT APPROVAL

DESIGN APPROVAL PROCESS (DAP)

CLIENT CONSULTATION FOR FINAL INPUT/FEEDBACK

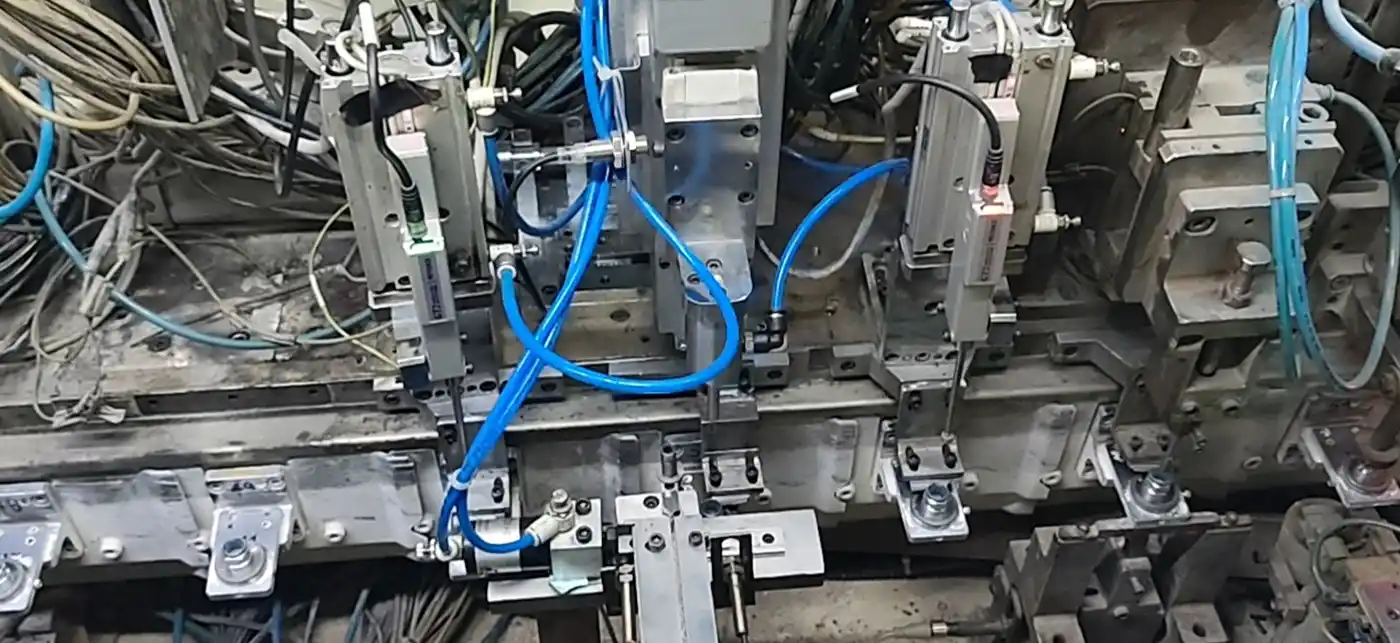

MANUFACTURING INITIATION POST FINAL APPROVAL

PRE-DISPATCH INSPECTION (PDI) BY CLIENT AT OUR FACILITY

DISPATCH & ON-SITE INSTALLATION

Designed specifically for detecting micro-cracks on metal components — especially in the automotive sector, where defects are invisible to the naked eye. Ensures only crack-free parts proceed to the next process

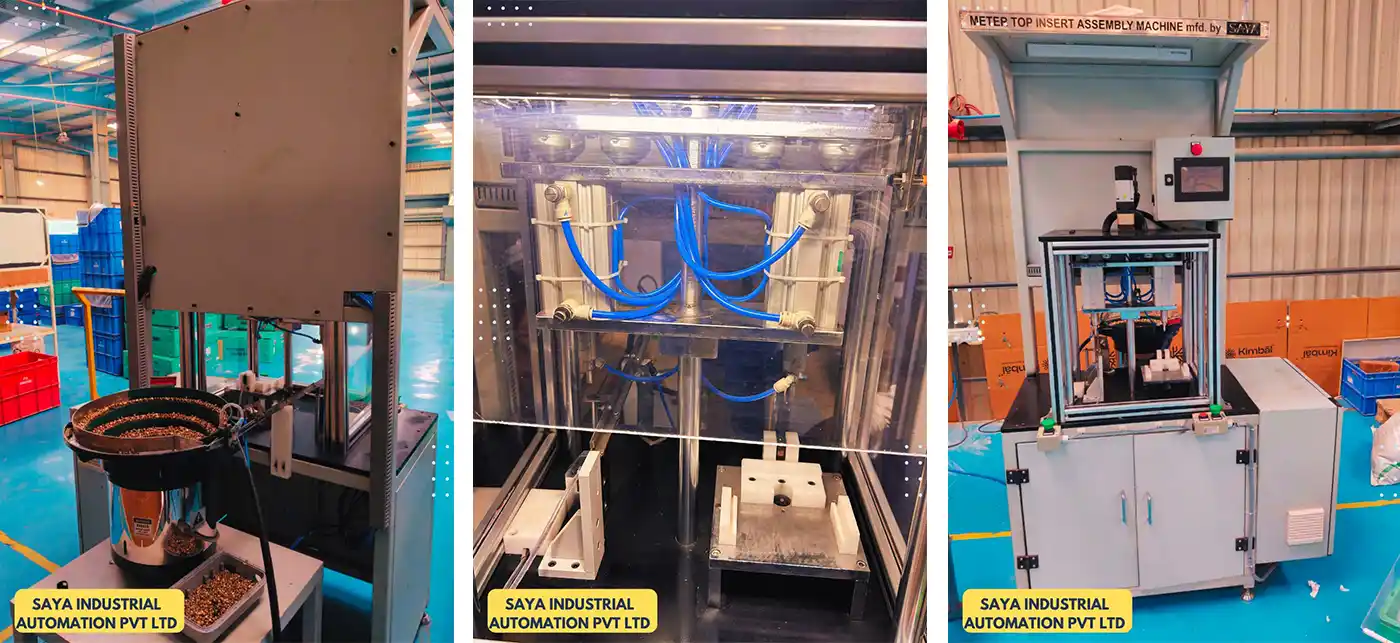

Designed for automatic pick & place of parts followed by automated nail assembly, ideal for high-volume production with minimal human intervention.

Designed for automated insertion of components (like inserts) into plastic parts such as electrical meter housings. Highly suitable for assembly lines requiring speed, accuracy, and error-proofing.

Type: Customized Control Panels

Specially designed for wire harness and wire assembly companies for recoiling different wire types with precision and speed. Ideal for batch processing and length-controlled winding.