Automation

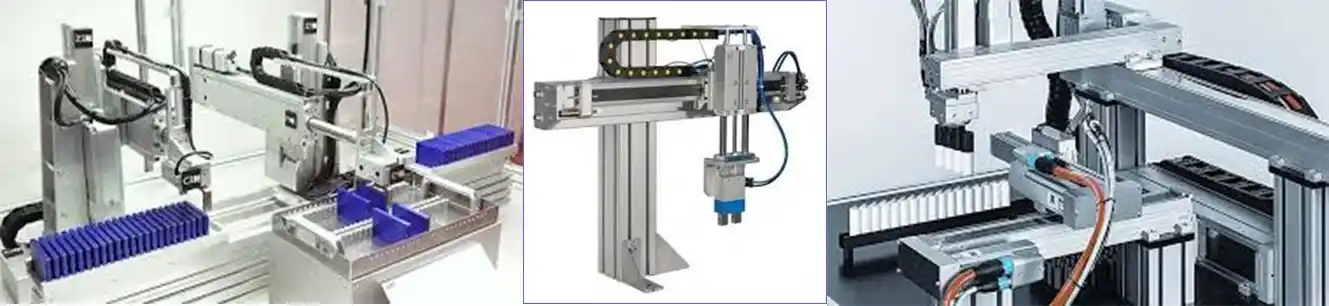

Pick and Place Automation System

An advanced pick and place solution designed to automate repetitive material handling tasks with speed, accuracy, and reliability. Ideal for manufacturing, assembly, and packaging operations.

High-Speed Performance with Servo Control

The system features precision-controlled servo motors to ensure smooth and accurate motion during pick and place cycles. Fast acceleration and deceleration improve cycle times and productivity.

Precision Linear Actuation

Linear movement is achieved using pneumatic or electric actuators, depending on application needs. These actuators provide stable, repeatable motion for consistent part handling.

Customizable End Effectors

The system supports a wide range of end effectors such as grippers, suction cups, or magnetic tools. These can be adapted to handle different shapes, sizes, and materials.

Fully Programmable Operation

Integrated with a PLC or industrial controller, the system offers full programmability for different tasks. Easily adjustable for product changes, speed variation, and sequence control.

Compact and Scalable Design

Designed to fit within tight production spaces while allowing for future scalability. Multiple systems can work together for multi-part or multi-station operations.

Solution for:-

- Electronics and PCB handling

- Small parts assembly

- Packaging and sorting lines

- CNC part feeding

- Food and beverage product placement

Key Benefits:

- Reduces manual labor and operational cost

- Increases consistency and quality

- Enhances production speed

- Minimizes errors and part damage

- Improves workplace safety